How is Hilco’s 3D printing different?

3D printing is commonly used by businesses to create prototype parts for the detection of issues in a part’s form, fit, or function. Yet 3D printing cannot always provide a complete assessment of a part’s functional performance because 3D material properties may be different than those used in injection molding.

Rather than using 3D printing to create a prototype part, Hilco - with the help of Stratasys 3D Polyjet technology – creates a prototype injection mold that fits in our standard injection molding machines allowing us to produce sample parts with production level equipment utilizing the specified production material. Not only are customers able to evaluate the off-tool part performance, but we are also able to evaluate the mold design and performance which enables us to make adjustments prior to making costly production molds.

Our 3D Printing Capabilities

Maximum Part Size

3D Printed Plastic: 10"x13"

Rapid Prototype Aluminum: 18"x27"

Everything In-House

Design, 3D Printing All in One Place

Custom Projects

If you have something in mind that might not fit these specs, reach out. Our capabilities are always changing.

Benefits of 3D Printing

Lead Time Reduction

Average Lead Time Savings: 70%-90%

Cost Reduction

Average Cost Savings 50-70%

Spec Resins

Functional evaluation with production plastics

Early Confirmation

Validate part performance and tool design -Validate thermoplastic selection

Material Selection & Tool Life

3D printing is commonly used by businesses to create prototype parts for the detection of issues in a part’s form, fit, or function. Yet 3D printing cannot always provide a complete assessment of a part’s functional performance because 3D material properties may be different than those used in injection molding.

With the help of Stratasys 3D Polyjet technology, we can now print an injection mold that fits in our standard injection molding machine.

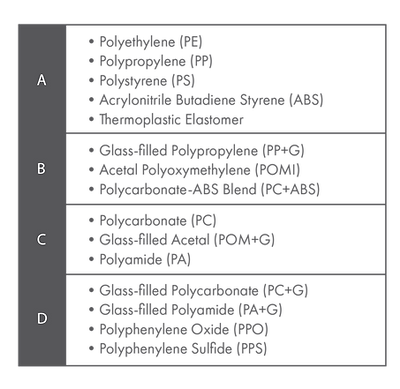

Figure 1 below shows the estimated number of parts obtained per tool, based on type of material used. Material types detailed in figure 2.

Figure 1

Figure 2